Position sensors in action

See our position sensors being put to the test at our Application Development Center in Nordborg, Denmark.

Play video

PLUS+1® compliant

All sensors are PLUS+1® compliant. With simple and intuitive interfaces, this software platform offers seamless integration with development and service tools, to bring products faster to market while making it easy to keep machines current with parameter adjustments and software updates. Furthermore, real-time, remote access makes staying up to date even easier.

Read more on PLUS+1® compliance

Documents

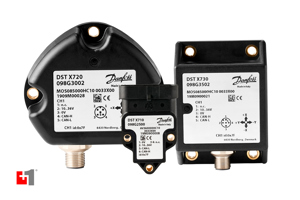

Product range

Articles

The demand for sensor technology is rapidly expanding. To comply with safety as well as environmental regulations, mobile hydraulic producers require more and more sensors in all machine types. Choosing the right sensor is crucial. We have made a checklist of key things to consider in your sensor specification.

Read the case study