Unleash your store’s potential and optimize food safety

Danfoss Smart Store solutions help build the supermarkets of tomorrow by reducing costs, minimizing environmental impact, and finding a competitive advantage, while safeguarding food safety. Every day, we are dedicated to making your store smarter and more energy efficient.

Climate friendly and efficient heating and cooling represent a huge potential for supermarkets to reduce their operational costs while contributing to decarbonization and reducing food loss. Danfoss Smart Store solutions are constantly expanded and developed in close cooperation with the global food retail community and is already proven in more than 50,000 installations.

What's in it for you?

- Use smart refrigeration control to reduce operating costs

- Connect to the internet to eliminate food waste and reduce service costs

- Sustainable refrigeration as a long-term decision

- Integrate each store’s systems to gain economies of scale

- Reduce energy prices by optimizing demand

Journey towards a net-zero Supermarket

Discover our innovations for helping you cut energy costs, reduce emissions, and prepare your supermarket for a more energy-efficient future.

Explore the Smart Store ebook

Experience real supermarket efficiency

Real settings. Real solutions. Real results.

The need for energy efficiency is more real in food retail than anywhere else. You can say the same about the combined Smart Store supermarket and Danfoss Application Development Center in Nordborg — it’s as real as it gets. Featuring only existing cooling and heating technologies relevant to the food retail sector — in a fully operational supermarket — this is the place to experience real, relatable, and reliable supermarket efficiency in action.

Food retail solutions in action

Watch our food retail solutions video series that showcases end-to-end Danfoss solutions across key food retail applications, supporting the journey toward more sustainable and energy-efficient stores.

Learning

Want to know more about our smart store solutions?

A series of webinars led by Danfoss experts, where you'll explore cutting-edge solutions for energy efficiency. These sessions offer practical insights, showcase best practices, and delve into real-world applications that can transform your approach to energy management. Join us to enhance your understanding and discover how these innovative solutions can be applied to achieve greater efficiency in various settings.

The following session are available:

- CO2 Booster systems

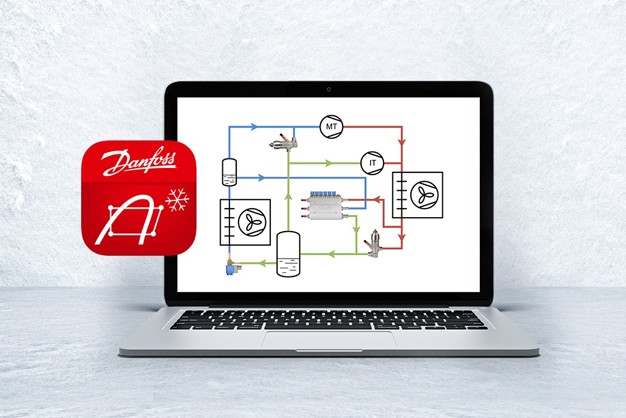

- HPV & GBV in Coolselector2/ Parallel IT system

- Case/Cold Room control and components

- Transcritical ejector systems. LP ejector

- IT & HP ejector

- LE & LE+HP ejector

- Heat Recovery in CO₂ systems & HRU

Discover the various solutions we offer to enhance supermarket efficiency through our engaging short smart store videos. These videos guide you through the innovative applications within a smart supermarket, showcasing how our technologies work together to optimize operations. From energy management to reducing food loss, each solution is designed to create a more sustainable and efficient supermarket environment.

Read more about how supermarkets can achieve significant energy savings with proper rail heat control.

With the world’s population expected to reach 10 billion people by 2050, sustainable food retail and storage are more important than ever.

Optimizing rail heat control for energy-efficient supermarkets

Rail heat control in supermarket HVAC-R systems is often overlooked, yet it holds significant potential for energy savings. Join our RETHINK Live event to explore how fine-tuning rail heat settings can lead to impactful energy reductions.

Sign up here

Experience the Danfoss Smart Store — Virtually

Exclusive on demand tour of Danfoss Smart Store and Application Development Center.

Experience it here

Software

Unlock new possibilities with Coolselector®2. Optimize your transcritical CO2 systems with precision and efficiency—start designing today. This tool takes the full refrigeration system into account.

Try out the new heat recovery tool that helps you analyze your heat source and consumption. Looking at the heat source, not the full HVAC-R system, the tool links data with current energy prices for insights into your operation.

Highlighted products

The CCMT is a highly reliable electric pressure regulating valve optimized for transcritical CO₂ refrigeration. The valve has versatile applications in the transcritical system.

Danfoss’ range of universal MCX programmable controllers offers the functionality and reliability you need to get the best out of your heating, ventilation, air-conditioning and refrigeration (HVAC/R) equipment.

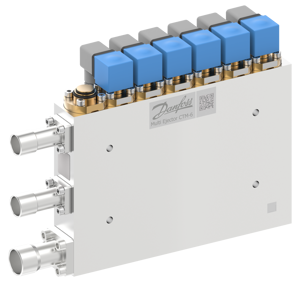

The Danfoss Multi Ejector Solution™ ensures that transcritical CO₂ applications for retailers become energy efficient in any climate.

Refrigeration pressure transmitters are used for commercial air-conditioning and for commercial and industrial refrigeration applications. They are made in stainless steel to be compatible with fluorinated and natural refrigerants and laser welding with no soft seals ensure hermetic tightness for decades.

Refrigeration temperature sensors are used for applications within air-conditioning as well as commercial and industrial refrigeration applications. The Pt 1000 sensor element meets the DIN/IES 751 class B requirements and ensures an accurate and reliable temperature signal applicable for regulation, safety, and data logging.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | A complete portfolio of CO₂ refrigeration solutions | Polish | Poland | 27 Jun, 2023 | 16.7 MB | |

| Brochure | Brochure_ADAP-KOOL_Evaporator_Controllers | Polish | Poland | 30 May, 2023 | 4.6 MB | |

| Brochure | Brochure_ADAP-KOOL_Evaporator_Controllers | French | France | 17 Mar, 2020 | 1.2 MB | |

| Brochure | Brochure_ADAP-KOOL_Evaporator_Controllers | Russian | Central Asia Unit | 23 Apr, 2020 | 3.7 MB | |

| Catalog | Danfoss CO2 catalogue - Components and controls for CO2 applications | Dutch, Flemish | Netherlands | 17 Apr, 2025 | 6.7 MB | |

| Catalog | Danfoss CO2 catalogue - Components and controls for CO2 applications | Italian | Italy | 17 Jul, 2024 | 4.3 MB | |

| Catalog | Danfoss CO2 catalogue - Components and controls for CO2 applications | Spanish, Castilian | Multiple | 18 Jul, 2024 | 1.2 MB | |

| Catalog | Danfoss CO2 catalogue - Components and controls for CO2 applications | French | France | 18 Oct, 2024 | 1.4 MB | |

| Catalog | Danfoss CO2 catalogue - Components and controls for CO2 applications | English | Multiple | 24 Nov, 2025 | 1.4 MB | |

| Brochure | Discover the opportunities of CO2 refrigeration | English | Multiple | 24 Nov, 2025 | 35.1 MB | |

| White paper | How supermarkets can boost energy savings with proper rail heat control | English | Multiple | 08 Dec, 2025 | 4.1 MB | |

| Brochure | Overview brochure: ADAP-KOOL® Evaporator Controllers | English | Multiple | 21 Oct, 2025 | 1.5 MB | |

| Brochure | Overview brochure: Evaporator Controllers | Italian | Italy | 22 May, 2024 | 934.1 KB | |

| Brochure | Overview brochure: Evaporator Controllers | Spanish, Castilian | Spain | 24 Apr, 2024 | 2.9 MB | |

| Brochure | Overview brochure: Pack Controllers | English | Multiple | 02 Feb, 2026 | 877.8 KB | |

| Brochure | Overview brochure: System Managers (Global) | Danish | Multiple | 17 Mar, 2016 | 1.5 MB | |

| Brochure | Overview brochure: System Managers (Global) | Portuguese | Multiple | 01 Feb, 2016 | 1.6 MB | |

| Brochure | Overview brochure: System Managers (Global) | Finnish | Multiple | 01 Feb, 2016 | 1.5 MB | |

| Brochure | Overview brochure: System Managers (Global) | Spanish, Castilian | Multiple | 01 Feb, 2016 | 1.5 MB | |

| Brochure | Overview brochure: System Managers (Global) | Russian | Multiple | 02 Jul, 2019 | 6.8 MB | |

| Brochure | Overview brochure: System Managers (Global) | Italian | Multiple | 17 Mar, 2016 | 1.5 MB | |

| Brochure | Overview brochure: System Managers (Global) | German | Multiple | 01 Feb, 2016 | 1.6 MB | |

| Brochure | Overview brochure: System Managers (Global) | Chinese | Multiple | 18 Mar, 2016 | 2.2 MB | |

| Brochure | Overview brochure: System Managers (Global) | Swedish | Multiple | 01 Feb, 2016 | 1.5 MB | |

| Brochure | Overview brochure: System Managers (Global) | Korean | Multiple | 17 Mar, 2016 | 1.8 MB | |

| Brochure | Save energy and protect the environment with CO2 solutions | Spanish, Castilian | Spain | 09 Jan, 2024 | 25.4 MB | |

| Brochure | Save energy and protect the environment with CO2 solutions | Italian | Italy | 12 Dec, 2023 | 16.5 MB | |

| Brochure | Save energy and protect the environment with CO2 solutions - Special version for Food Retail | French | Multiple | 02 Jul, 2018 | 3.4 MB | |

| Brochure | Save energy and protect the environment with CO2 solutions - Special version for Food Retail | Ukrainian | Ukraine | 20 Jun, 2023 | 14.6 MB | |

| Brochure | Save energy and protect the environment with CO2 solutions - Special version for Food Retail | German | Multiple | 14 Jun, 2023 | 11.7 MB | |

| Brochure | Save energy and protect the environment with CO2 solutions - Special version for Food Retail | French | France | 04 Aug, 2022 | 11.7 MB | |

| Brochure | Smart Store Brochure | English | Multiple | 16 Oct, 2025 | 5.2 MB |

Case stories

A busy Danish supermarket reduced its annual heating bill by 89.7% and its CO₂ footprint by 6.7 tons a year by making use of the waste heat from its refrigeration system.

A Danish supermarket fulfills 95 percent of its heating demand from its own cooling display cases. The chain has installed Danfoss heat recovery units and managed to halve its CO2 footprint in five years. Imagine if this was done in all supermarkets in the world.

Danfoss Enterprise Services in Baltimore delivers real-time insight to 14,000 supermarket operators and the demand is growing.

The supermarket aktiv & irma in Oldenburg, Germany, has pressed the start-button to a solution enabling it to store and generate electricity. The grocery store’s manager calls it a leap forward in energy supply. Danfoss and SMA have helped make it happen. Learn how.

A stronger environmental profile and energy savings of approx. 30% from a cooling solution that can be expanded as needed. These are the results so far for Danish organic food company Aarstiderne. Since Q1 2018, the company’s facilities at Barritskov, Denmark, have relied on a CO₂ cooling system with Danfoss components delivered by refrigeration installer company JF Køleteknik A/S.

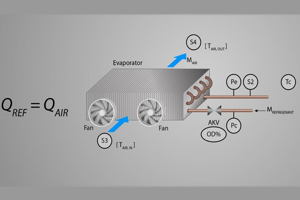

Danfoss offers a complete portfolio of gas and liquid ejectors that provide significant benefits in CO2 refrigeration applications. Here we take a closer look at these offerings: the Multi Ejector Low Pressure (LP), the Multi Ejector High Pressure (HP), and the Liquid Ejector (LE). All three ejector products are only available as a complete Multi Ejector Solution™ where the ejector is bundled with the AK-PC 782A pack controller to provide the robust system controls necessary for efficient and reliable operation.

Articles

This year’s UN Food Day is a unique one. While the world is still grappling with pandemic related supply chain challenges, I can’t help but reflect on the state of food transport.

Before digging into the secret of Danfoss adaptive defrost, let’s first take a look at the most common methods of defrosting refrigerated display cases, and why they’re necessary.

If you work in facilities or energy management for a food retailer, change is something you handle every day. When the way we live, work, or shop changes, new food retail technology is close behind.

Around the world, there is little doubt that CO2 is fast becoming food retailers’ refrigerant of choice. At Danfoss alone, we’re currently seeing supermarkets switching to CO2 refrigeration systems at a rate of around 10,000 a year—and that number is growing fast.

In the last few years, supermarkets have made great advances in energy efficiency - reducing both overhead and their environmental impact.

Reducing energy use is valuable, and always will be. But there’s another side to reducing energy costs. Increasingly, the biggest potential saving isn’t only in using less energy; it’s in optimizing how it’s used, and when.

When you stop and think about it, it’s a little strange that supermarkets usually pay to heat their premises and water while their refrigeration system works overtime to move heat energy outside.