High-temperature heat pumps for industrial process heat systems

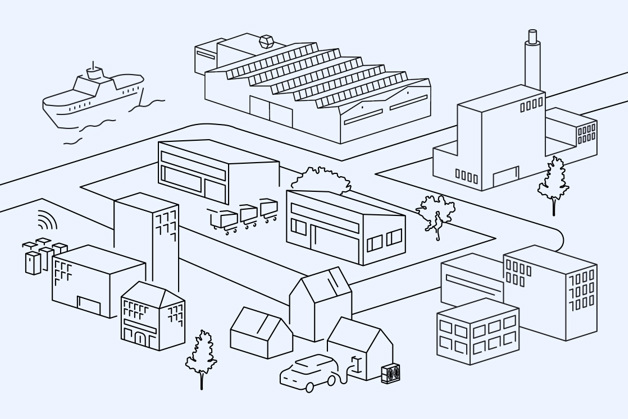

Industrial heat pumps are at the forefront of decarbonizing essential sectors like food and beverage, pulp and paper, chemicals, and textiles. These industries rely on high-temperature steam for critical processes such as drying, sterilization, and boiling. With a significant portion of industrial heat demand falling below 100°C, mature and reliable heat pump technology is already available to facilitate this transition.

Danfoss is your dedicated partner in navigating the shift to sustainable industrial heating systems. For processes requiring higher temperatures, we are pushing performance limits with technologies capable of delivering hot water up to 120°C now, with advancements towards 150°C on the horizon.

Spotlight: decarbonizing the food and beverage industry

A prime example of our technology in action is in the brewery sector. We have successfully partnered with breweries to refurbish older ammonia (NH₃) cooling systems and replace fossil-fuel-based boilers. By integrating hydrocarbon-based industrial heat pumps, these facilities can now generate high-temperature process heat and steam, dramatically reducing their carbon footprint and moving towards a fossil-free operation.

Industrial heat pumps can replace fossil fuels by converting electrical energy input into thermal output.

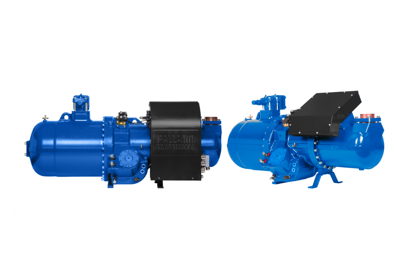

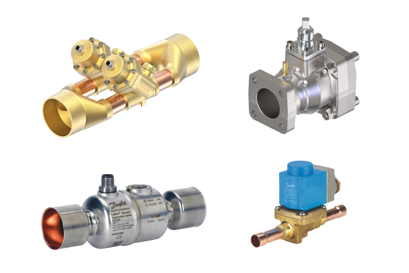

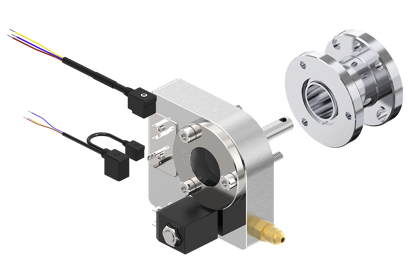

Product portfolio

Proven solutions for your industrial heating needs

As the demand for energy continues to rise and the need to replace fossil fuel boilers becomes more urgent, decarbonizing the industrial process heat sector is a critical priority. Heat pumps, with their proven technology and growing potential, offer a compelling solution.

Danfoss provides the expertise and technology to unlock the full potential of high-temperature heat pumps, enhancing both process heating efficiency and overall industrial heating performance.

Our comprehensive offering supports every stage of your project—from early system design and simulation to collaborative development partnerships—ensuring reliable, high-performance industrial heat pump solutions built for the future.

Key benefits of our solutions for industrial heat pumps:

- Complete portfolio in one place: access a full range of components, delivered by experienced experts in industrial heat pumps

- Energy efficiency: benefit from low energy consumption for efficient and sustainable process heating and industrial heating

- Sustainable operations: our solutions are optimized for natural and low-GWP refrigerants, including Ammonia (NH₃), CO₂, and hydrocarbons, to support your environmental goals

- Optimized costs and reliability: achieve reduced applied costs, short payback time, and easy serviceability for maximum reliability and performance

- Global support: rely on our global customer support to ensure long-term success with your advanced high-temperature heat pump solutions

Explore solutions for NH₃ (ammonia), CO₂, hydrocarbons, and low-GWP refrigerants in our latest brochure.

Read more here

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | Alsmart® Master your HVAC symphony | French | France | 19 Dec, 2024 | 4.5 MB | |

| Brochure | BOCK CO2 compressor program | English | Multiple | 06 Aug, 2024 | 7.6 MB | |

| Brochure | BOCK LG compressor range | English | Multiple | 18 Dec, 2023 | 1.1 MB | |

| Brochure | BOCK UL CO2 compressor program | English | Multiple | 09 Aug, 2024 | 2.0 MB | |

| Brochure | Brochure_Electric Expansion Valves overview | English | Multiple | 08 Aug, 2025 | 3.2 MB | |

| Brochure | Brochure_Electric Expansion Valves overview | Polish | Poland | 30 Jun, 2023 | 1.8 MB | |

| Promotion material | COM Compressor Oil Management brochure | English | Multiple | 19 Dec, 2025 | 752.1 KB | |

| Promotion material | COM Compressor Oil Management brochure | Italian | Italy | 12 Jan, 2024 | 1.3 MB | |

| Promotion material | COM Compressor Oil Management brochure | Spanish, Castilian | Spain | 12 Jan, 2024 | 434.9 KB | |

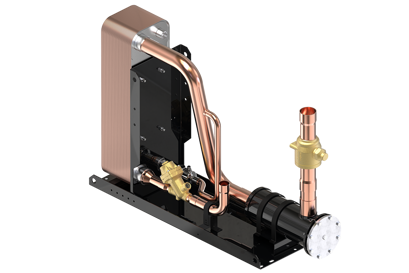

| Brochure | Danfoss pre-assembled Economizer | English | Multiple | 30 Oct, 2024 | 2.2 MB | |

| Brochure | Danfoss Turbocor Compressor Specification Sheet | English | Multiple | 13 Aug, 2024 | 8.0 MB | |

| Brochure | eBook | Alsmart® Master your HVAC symphony | English | Multiple | 20 Feb, 2026 | 3.0 MB | |

| Data sheet | Gas detecting sensor, type DGS | Polish | Multiple | 06 Mar, 2025 | 6.2 MB | |

| Data sheet | Gas detecting sensor, type DGS | French | Multiple | 06 Mar, 2025 | 6.2 MB | |

| Data sheet | Gas detecting sensor, type DGS | German | Multiple | 06 Mar, 2025 | 6.2 MB | |

| Data sheet | Gas detecting sensor, type DGS | English | Multiple | 12 Dec, 2024 | 6.0 MB | |

| Data sheet | MicroPlate™ HeatExchanger, Type H48T-CH | English | Multiple | 12 May, 2025 | 2.7 MB | |

| Data sheet | NRV check valve CO2 | English | Multiple | 16 Sep, 2025 | 1.0 MB | |

| Brochure | Overview Brochure: Filter driers | Spanish, Castilian | Spain | 08 Mar, 2024 | 11.8 MB | |

| Brochure | Overview Brochure: Filter driers | Polish | Multiple | 20 Nov, 2018 | 11.7 MB | |

| Brochure | Overview Brochure: Filter driers | Indonesian | Multiple | 05 Jul, 2016 | 2.5 MB | |

| Brochure | Overview Brochure: Filter driers | French | France | 05 Feb, 2024 | 19.3 MB | |

| Brochure | Overview Brochure: Filter driers | Italian | Multiple | 05 Apr, 2024 | 12.2 MB | |

| Brochure | Overview Brochure: Filter driers | Chinese | Multiple | 20 Nov, 2018 | 11.8 MB | |

| Brochure | Overview Brochure: Filter driers | Russian | Multiple | 27 Jun, 2019 | 11.6 MB | |

| Brochure | Overview Brochure: Filter driers | German | Multiple | 20 Nov, 2018 | 11.8 MB | |

| Brochure | Overview Brochure: Filter driers | Danish | Multiple | 20 Nov, 2018 | 11.7 MB | |

| Brochure | Overview Brochure: Filter driers | English | Multiple | 08 Apr, 2024 | 2.4 MB | |

| Brochure | Overview Brochure: Filter driers | Swedish | Multiple | 20 Nov, 2018 | 11.7 MB | |

| Brochure | Overview Brochure: Filter driers | Portuguese | Multiple | 20 Nov, 2018 | 11.7 MB | |

| Brochure | Overview brochures: Electronic Expansion Valves | German | Multiple | 15 Nov, 2022 | 1.5 MB | |

| Application guide | Screw compressors - K1 Series - Palladio | English | Multiple | 23 Jul, 2024 | 12.9 MB | |

| Application guide | Scroll compressors PSG605 to PSG800 | English | Multiple | 10 Jun, 2025 | 3.9 MB | |

| Data sheet | Solenoid valve Type EVR 2 - EVR 40 | English | Multiple | 16 Sep, 2025 | 4.1 MB | |

| Data sheet | Solenoid valve Type EVR 2 - EVR 40 Version 2 | Russian | Multiple | 28 Oct, 2018 | 9.2 MB | |

| Data sheet | Solenoid valve Type EVR 2 - EVR 40 Version 2 | Chinese | Multiple | 28 Oct, 2018 | 9.2 MB | |

| Data sheet | Solenoid valve Type EVR 2 - EVR 40 Version 2 | Korean | Multiple | 28 Oct, 2018 | 9.3 MB | |

| Data sheet | Solenoid valve Type EVR 2 - EVR 40 Version 2 | German | Multiple | 28 Oct, 2018 | 9.1 MB | |

| Data sheet | Solenoid valve Type EVR 2 - EVR 40 Version 2 | French | Multiple | 28 Oct, 2018 | 9.1 MB | |

| Data sheet | Solenoid valve Type EVR 2 - EVR 40 Version 2 | Portuguese | Multiple | 28 Oct, 2018 | 9.1 MB | |

| Data sheet | Solenoid valve Type EVR 2 - EVR 40 Version 2 | Japanese | Multiple | 28 Oct, 2018 | 9.2 MB | |

| Data sheet | Solenoid valve Type EVR 2 - EVR 40 Version 2 | Spanish, Castilian | Multiple | 28 Oct, 2018 | 9.1 MB | |

| Data sheet | Solenoid valve Type EVR 2 - EVR 40 Version 2 | Italian | Multiple | 28 Oct, 2018 | 9.1 MB | |

| Data sheet | Staging valve Type PTS 13L - 18L - 27L - 38P | English | Multiple | 16 Oct, 2025 | 4.8 MB | |

| Data sheet | Superheat Controller and stepper valve driver Type EKE 100 | English | Multiple | 20 Aug, 2024 | 2.6 MB | |

| Brochure | Z-design MPHEs for chillers Economic and environmental savings in cooling | English | Multiple | 23 Mar, 2023 | 2.4 MB | |

| Brochure | Z-design MPHEs for chillers Economic and environmental savings in cooling | Chinese | Multiple | 11 May, 2016 | 21.6 MB |

Simulation services

Advancing technology through innovation and partnership

We are committed to pushing the boundaries of what's possible in industrial heating, with a clear focus on developing solutions for temperatures up to 200°C. Through advanced services and collaborative research, we help our partners accelerate development and secure their investments.

The A3S service—Advanced System Simulation Services

- Accelerate time to market: reduce development time and the need for extensive lab testing

- Save on development costs: optimize the use of resources, including personnel and lab capacity

- Optimize systems: fine-tune capacity, efficiency, and refrigerant charge with a multi-component approach

- Secure investment: validate component selections and operating maps before committing to physical prototypes

The SuPrHeat Project: pushing temperatures above 100°C

The SuPrHeat Project: pushing temperatures above 100°C The SuPrHeat (Sustainable Process Heating) project is a cross-disciplinary research and development initiative with 16 partners across Europe. This project has been instrumental in advancing high-temperature heat pump technology.

Key achievement: A 500 kW high-temperature heat pump is now operational at the Danish Technological Institute (DTI). Its key specifications include:

- A pentane/butane cascade system capable of achieving a maximum condensing temperature of 150°C

- Integration of Danfoss industrial refrigeration components and BOCK® compressors

- A containerized design that eliminates the need for ATEX zone requirements

This project demonstrates the viability of high-temperature heat pumps using natural refrigerants for demanding industrial applications.

If you are interested in co-development projects or for an introduction to our solutions, get in touch.

Learn more about the project here.

Explore more technologies for comfort and process heating and cooling systems

Energy efficient HVAC systems are a key lever to decarbonize buildings. The energy costs, decarbonization goals, and evolving regulations are hastening the shift to greener energy in commercial and industrial heating and cooling. Hydronic heat pumps are playing a central role in this sustainability-driven journey for heating systems. Danfoss is your trusted partner, offering a comprehensive solution. From heat source to distribution, we provide an extensive portfolio, application expertise, and market-leading simulation and testing capabilities.

With our extensive portfolio, we offer a powerful combination of expertise, product and refrigerant options that will enhance your system designs.

Explore here

Case stories

Ringsted District Heating Company (DHC)—a large district heating utility in Denmark—has reduced its reliance on fossil fuels by 97% after Unicool installed an innovative heat recovery system using Geoclima heat pumps built with Danfoss Turbocor® oil-free compressor technology. With increasingly strict environmental regulations and growing costs, district heat plants are moving away from fossil fuels and turning to renewable energy—and innovative technology such as electric heat pumps and heat recovery—to reduce their environmental impact and maintain affordable heating.

At Frederikshavn District Heating Utility (DHU), a 14 MW gas boiler is utilized during the cold months to ensure sufficient heat supply to the Frederikshavn community. A project was initiated by ME Production, involving Danfoss and heat pump OEM partner Energy Machines, to enhance energy utilization by recovering boiler flue gas heat. This was accomplished by modifying the existing economizer to increase the recovered capacity and boost boiler capacity with the resulting condensing function.

For just over a year, the Van Hulst chick hatchery in Veldhoven (Netherlands) went completely without natural gas. Two-stage heat pumps now supply the heat and cooling needed to maintain the temperature of the chicken eggs. The new solution is climate-friendly, thanks to the use of natural refrigerants and operation with solar electricity – and lowers energy costs by approx. 30,000 euros per year.