Reduce costly downtime with a fast replacement

Maintain uptime with a fast alternative to repair when there is a time critical situation. If an AC drive fails, the DrivePro® Exchange service can quickly exchange any AC drive to a new unit of the same type to ensure as little production delay as possible.

How to order DrivePro® Exchange

Avoid costly production stop

Count on a fast delivery of your replacement AC drive and avoid the costs and downtime for repair. Ensure a seamless exchange and reduce the time that the operation does not run optimally or is in downtime.

With DrivePro® Exchange, you get a replacement of equal size, power, performance and software or better for the best performance match.

Rest assured that your drive is well-taken care of and performs optimally from installation, throughout the use, and after the end of its lifecycle.

How it works

Features and benefits

-

Utilize an alternative solution to drive repair when time matters

- Obtain the fastest and most cost-efficient solution when an AC drive fails

-

24 hours exchange AC drive shipping after ordering

- Fast delivery of exchange AC drive to your site

- Prevent excessive downtime on the production line

-

Ensure the best dimensional match for fast installation

- Avoid turnover losses due to lost process availability during replacement

-

Power, performance, and software of exchange AC drive is equal to or better than that of the failed AC drive

- Ongoing reliability thanks to best performance match

FAQ

What products are covered by the DrivePro® Exchange service?

With DrivePro® Exchange, we support all Danfoss AC drives with a new or active lifecycle status.

Read more about the lifecycle management model

What is the difference between the DrivePro® Exchange and DrivePro® Retrofit services?

With DrivePro® Exchange, we always replace the drive with the same type of product.

With DrivePro® Retrofit, we always replace the drive with its successor product or the best alternative product from our portfolio of AC drives in the new and active lifecycle stages.

Read more about the lifecycle management model

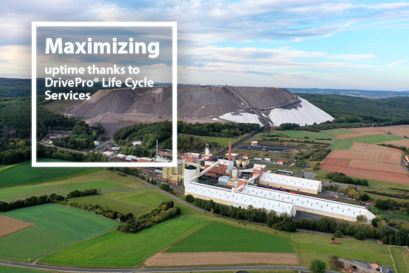

Prolong the lifetime of your AC drives

DrivePro® Lifecycle Services are designed to support your business through the different lifecycle stages of your AC drive.

Rest assured that your drive is well-taken care of and performs optimally from installation, throughout use, and after the end of its lifecycle.

DrivePro® Services for the whole lifecycle

Danfoss AC drives follow four lifecycle phases: New, Active, Limited, and Inactive. Different DrivePro® services are available throughout each of these phases.

Discover all services

Circularity is at the core of DrivePro® DNA

Prolong the lifetime of your AC drives with tailored lifecycle services. This reduces waste generation and raw material consumption through repair, maintenance, and reuse of products and parts — also known as product circularity.

Learn more about circularity

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Fact sheet | DrivePro Exchange | English | Multiple | 17 Jul, 2024 | 1.0 MB | |

| Fact sheet | DrivePro Exchange - Austria | German | Austria | 03 May, 2022 | 966.9 KB | |

| Fact sheet | DrivePro Exchange - Bulgarian | Bulgarian | Multiple | 03 May, 2022 | 973.2 KB | |

| Fact sheet | DrivePro Exchange - Chinese | Chinese | Multiple | 25 Sep, 2024 | 610.7 KB | |

| Fact sheet | DrivePro Exchange - Czech | Czech | Multiple | 03 May, 2022 | 964.6 KB | |

| Fact sheet | DrivePro Exchange - Danish | Danish | Multiple | 03 May, 2022 | 968.9 KB | |

| Fact sheet | DrivePro Exchange - Dutch | Dutch, Flemish | Multiple | 03 May, 2022 | 965.1 KB | |

| Fact sheet | DrivePro Exchange - Finnish | Finnish | Multiple | 03 May, 2022 | 965.0 KB | |

| Fact sheet | DrivePro Exchange - French | French | Multiple | 25 Sep, 2024 | 569.6 KB | |

| Fact sheet | DrivePro Exchange - German | German | Switzerland | 03 May, 2022 | 966.9 KB | |

| Fact sheet | DrivePro Exchange - German | German | Multiple | 25 Sep, 2024 | 582.3 KB | |

| Fact sheet | DrivePro Exchange - Hungarian | Hungarian | Multiple | 03 May, 2022 | 970.7 KB | |

| Fact sheet | DrivePro Exchange - Italian | Italian | Multiple | 25 Sep, 2024 | 559.2 KB | |

| Fact sheet | DrivePro Exchange - Korean | Korean | Multiple | 03 May, 2022 | 1.0 MB | |

| Fact sheet | DrivePro Exchange - Polish | Polish | Multiple | 03 May, 2022 | 970.4 KB | |

| Fact sheet | DrivePro Exchange - Portuguese | Portuguese | Multiple | 25 Sep, 2024 | 559.4 KB | |

| Fact sheet | DrivePro Exchange - Romanian | Romanian, Moldavian, Moldovan | Multiple | 03 May, 2022 | 971.0 KB | |

| Fact sheet | DrivePro Exchange - Russian | Russian | Multiple | 03 May, 2022 | 970.7 KB | |

| Fact sheet | DrivePro Exchange - Serbian | Serbian | Multiple | 03 May, 2022 | 969.6 KB | |

| Fact sheet | DrivePro Exchange - Slovak | Slovak | Multiple | 03 May, 2022 | 966.1 KB | |

| Fact sheet | DrivePro Exchange - Spanish | Spanish, Castilian | Multiple | 25 Sep, 2024 | 568.6 KB | |

| Fact sheet | DrivePro Exchange - Ukraine | Ukrainian | Multiple | 03 May, 2022 | 974.2 KB | |

| Fact sheet | DrivePro Exchange - US English | English | United States | 19 Sep, 2024 | 467.4 KB |

Case stories

ITALY: Unilever’s Caivano plant ice cream tunnel now enjoys enhanced ventilation efficiency with EC+ concept. Condition-based monitoring boosts productivity.

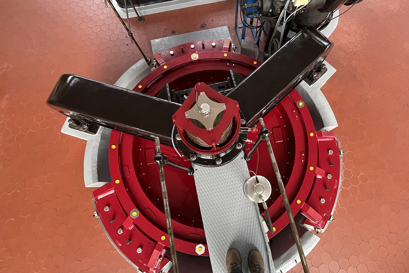

CZECHIA: When 80-year-old gears were replaced by variable speed control at the Albrechtice hydropower plant, power production increased by 10%.

Belgium: Thanks to Danfoss DrivePro® services, LuxFly has achieved 99,5% uptime in Europe’s largest vertical wind tunnel that is used for skydiving.

SCOTLAND: The Rothes CoRDe plant, a biomass-fired combined heat and power (CHP) plant, ensured maximum uptime thanks to several DrivePro® Lifecycle Services.