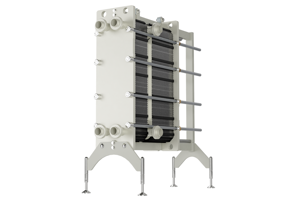

Our SONDEX® Free Flow plate heat exchangers are excellent choices for applications that use media with particle-rich contents, fouling tendency, or high viscosity. We customize each Free Flow heat exchanger to suit your application and media type. The contact-free plate channels ensure an unimpeded flow and long intervals between cleaning.

We set the new standard for improved performance and reliability when your media require gentle treatment and are unsuitable for regular heat exchangers due to viscosity, fouling tendency, or particle contents.

Features and benefits

-

Gentle treatment and even distribution of the media provide the highest possible product output quality.

-

High heat transfer efficiency and extended intervals between cleaning ensure operation for an entire campaign with minimum downtime and maximum value for money.

-

Large plate gap designed to counteract fouling with sizeable plate channels and no stagnant zones.

SONDEX® Free Flow plates feature deep and wide channels that provide enough room for media that contain fibers and particles, or high-viscosity media. The channels allow for efficient heat transfer and an ideal flow.

Applications

- Dairy/food/beverage industry

- e.g. food production, like juice and alcohol processing - Sugar industry

- e.g. sugar production, such as concentration of sugar content in sugarcane juice - Biogas industry

- Wastewater industry

- Pulp and paper industry

- Mining industry

Technical specifications

- Connections from DN25 to DN500 (1” to 20”)

- Frames designed according to FEA and PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards

- Plate materials: AISI 304/316, titanium, SMO, Hastelloy*

- Gasket materials: EPDM-HT, NBR-HT, Viton*

- Plate heights up to 3.5 m (11.5 ft)

- Flow rates up to 1,600 m3/h (7,045 gpm)

- Plate gap from 5 to 12 mm (0.2” to 0.5”)

- Working pressure up to 10 bar (145 psi)

- Working temperatures from -20 °C to 180 °C (-4 °F to 356 °F)

*other materials available upon request

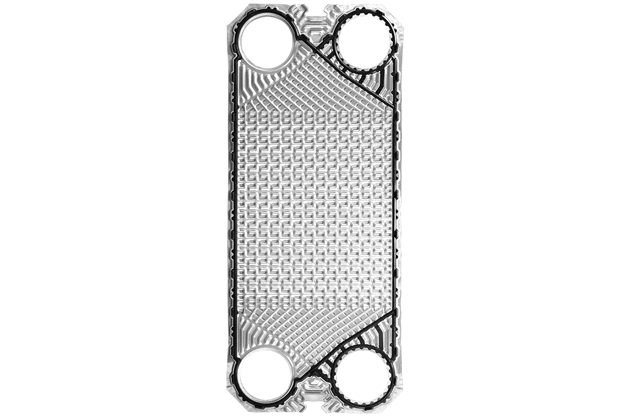

SONDEX® Free flow patterns

The SONDEX® Free Flow pattern is designed to treat media that is unsuitable for regular heat exchangers due to high viscosity, fiber and particle contents, or considerable risk of fouling.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | A world of heat exchangers | Romanian, Moldavian, Moldovan | Romania | 10 Oct, 2024 | 9.7 MB | |

| Brochure | A world of heat exchangers | Bulgarian | Bulgaria | 04 Oct, 2024 | 5.3 MB | |

| Brochure | A world of heat exchangers | English | Multiple | 15 Sep, 2025 | 4.7 MB | |

| Operating guide | DA - Gasketed and semi-welded Plate type heat exchangers | Danish | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | DE - Gasketed and semi-welded Plate type heat exchangers | German | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | EN - Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 02 Jun, 2025 | 9.6 MB | |

| Operating guide | FR - Gasketed and semi-welded Plate type heat exchangers | French | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Brochure | Gasketed plate heat exchangers - Next-generation heat transfer solutions | English | Multiple | 15 Sep, 2025 | 5.6 MB | |

| Operating guide | HU - Gasketed and semi-welded Plate type heat exchangers | Hungarian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | IT - Gasketed and semi-welded Plate type heat exchangers | Italian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | PL - Gasketed and semi-welded Plate type heat exchangers | Polish | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | RU - Gasketed and semi-welded Plate type heat exchangers | Russian | Multiple | 17 May, 2024 | 16.5 MB | |

| Brochure | SONDEX® Free Flow sugar brochure | English | Multiple | 27 Nov, 2024 | 7.2 MB | |

| Brochure | SONDEX® Traditional Plate Heat Exchangers | English | Multiple | 12 Feb, 2024 | 9.4 MB | |

| Operating guide | SV - Gasketed and semi-welded Plate type heat exchangers | Swedish | Multiple | 17 Nov, 2025 | 9.6 MB | |

| Operating guide | ZH - Gasketed and semi-welded Plate type heat exchangers | Chinese | Multiple | 05 Jun, 2025 | 9.6 MB | |

| Brochure | Брошура_Вдосконалені рішення теплообміну | Ukrainian | Ukraine | 01 Oct, 2025 | 3.8 MB |

Related products

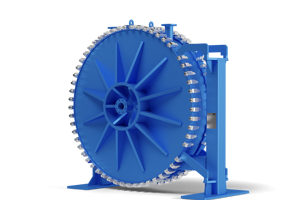

Our Plate and shell heat exchangers are perfect choices for condensation and steam heating duties. A fully welded plate pack makes the heat exchangers well-suited for handling aggressive media as well as high pressure levels and temperatures. Less space demanding and much lighter in weight, they are good replacements for shell and tube heat exchangers.

Exceptionally well-suited for sludges, slurries, waste water, fouling, liquids with high viscosity, and liquids that contain fibers and solids, our SONDEX® Spiral heat exchangers are the definitive solution for applications that require treatment of challenging fluids. The design allows for a countercurrent flow that makes it possible to achieve very close temperature approaches.

SONDEX® standard plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. We have the largest plate portfolio in the world, and customize each heat exchanger to meet your exact requirements. Innovative technologies and smart design make our traditional plate heat exchangers a stellar investment.

SONDEX® Free Flow plate heat exchangers are the preferred choice for applications that use media with particle-rich contents, fouling tendency, or high viscosity. Each Free Flow heat exchanger is customized to suit your application and media type, with contact-free plate channels for an unimpeded flow and long intervals between cleaning.

Case stories

Together with our long-term and trusted partner Geotermia Podhalańska in Poland, Danfoss Heat Exchangers is ready to take geothermal production to the next level.

Since its launch in 2016, the SONDEX® branch of Danfoss Brasil has worked hard to become the leading manufacturer of plate heat exchangers for customers across Latin America. In December 2017, the company took giant strides towards fulfilling its high ambitions when it delivered four evaporators to Bioenergética Aroeira for use in the production of sugarcane ethanol – the biggest delivery of its kind ever manufactured in Latin America.

Service

Our service team offers repairs, trouble shooting, upgrades, and on-site cleaning and maintenance of your plate heat exchanger solution. We always utilize genuine spare parts both for SONDEX® heat exchangers and our selection of other heat exchanger brands.

Gasketed plate heat exchanger service