What does that mean for you?

The deep and wide channels provide ample room for hard-to-handle media to flow effortlessly, ensuring gentle treatment of the output product and leading to sustainable quality improvements.

Since there is only line contact between the plates, even long and sticky particles will not get stuck and clog the heat exchanger.

The Free Flow plates are also well-suited for media that tend to cause fouling, and are designed with the fouling factor in mind. The channels allow for efficient heat transfer and an ideal flow regardless of the accumulated fouling. Because of this, cleaning can be postponed and you achieve longer operational uptime.

This enables a sugar producer, for example, to operate at full capacity throughout an entire campaign without losing valuable production time and product output.

Features and benefits

-

Ensures an unimpeded flow due to the deep channels and limited contact points between the plates. The large plate gap is designed to handle media that cause fouling and clog regular heat exchangers.

-

Extended operation time, with no cleaning needed, regardless of the media’s viscosity, fouling tendency, and particle contents.

-

Asymmetric patterns are available for applications with big flow rate differences. Taking the flow rate differences into account eliminates problems with air pockets, media maldistribution and low turbulence.

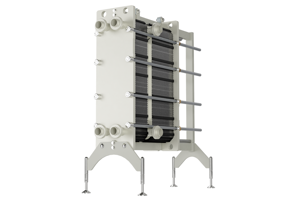

SONDEX® Free Flow plates feature deep and wide channels that provide enough room for media that contain fibers and particles, or high-viscosity media. The channels allow for efficient heat transfer and an ideal flow.

From design and construction to working principles, we take you through the key features behind these high-efficiency heat transfer solutions.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | A world of heat exchangers | Romanian, Moldavian, Moldovan | Romania | 10 Oct, 2024 | 9.7 MB | |

| Brochure | A world of heat exchangers | Bulgarian | Bulgaria | 04 Oct, 2024 | 5.3 MB | |

| Brochure | A world of heat exchangers | English | Multiple | 15 Sep, 2025 | 4.7 MB | |

| Operating guide | DA - Gasketed and semi-welded Plate type heat exchangers | Danish | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | DE - Gasketed and semi-welded Plate type heat exchangers | German | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | EN - Gasketed and semi-welded Plate type heat exchangers | English | Multiple | 02 Jun, 2025 | 9.6 MB | |

| Operating guide | FR - Gasketed and semi-welded Plate type heat exchangers | French | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Brochure | Gasketed plate heat exchangers - Next-generation heat transfer solutions | English | Multiple | 15 Sep, 2025 | 5.6 MB | |

| Operating guide | HU - Gasketed and semi-welded Plate type heat exchangers | Hungarian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | IT - Gasketed and semi-welded Plate type heat exchangers | Italian | Multiple | 05 Jun, 2025 | 9.1 MB | |

| Operating guide | PL - Gasketed and semi-welded Plate type heat exchangers | Polish | Multiple | 05 Jun, 2025 | 9.2 MB | |

| Operating guide | RU - Gasketed and semi-welded Plate type heat exchangers | Russian | Multiple | 17 May, 2024 | 16.5 MB | |

| Brochure | SONDEX® Free Flow sugar brochure | English | Multiple | 27 Nov, 2024 | 7.2 MB | |

| Brochure | SONDEX® Traditional Plate Heat Exchangers | English | Multiple | 12 Feb, 2024 | 9.4 MB | |

| Operating guide | SV - Gasketed and semi-welded Plate type heat exchangers | Swedish | Multiple | 17 Nov, 2025 | 9.6 MB | |

| Operating guide | ZH - Gasketed and semi-welded Plate type heat exchangers | Chinese | Multiple | 05 Jun, 2025 | 9.6 MB | |

| Brochure | Брошура_Вдосконалені рішення теплообміну | Ukrainian | Ukraine | 01 Oct, 2025 | 3.8 MB |

Related products

SONDEX® standard plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. We have the largest plate portfolio in the world, and customize each heat exchanger to meet your exact requirements. Innovative technologies and smart design make our traditional plate heat exchangers a stellar investment.

FAQ

What kind of heat exchanger is right for me?

The choice of heat exchanger depends on many factors. Our skilled sales engineers design the heat exchanger with the appropriate dimensions and correct specifications based on your input and requirements, to ensure that you receive a quality solution that performs optimally.

Which certificates are available for the heat exchangers?

Our heat exchangers are approved and certified according to industry standards and requirements. For specific details, please reach out to your local SONDEX® brand sales representative.

Where can I get a price list?

Please contact your local SONDEX® brand sales responsible.

How can I get a quotation?

Please contact your local SONDEX® brand sales office. For the most accurate quotation, please prepare the following data:

- Duty,

- Type of media,

- Pressure drop,

- Flow rate,

- Working pressure,

- Thermodynamic properties, Temperature,

- Working temperature.