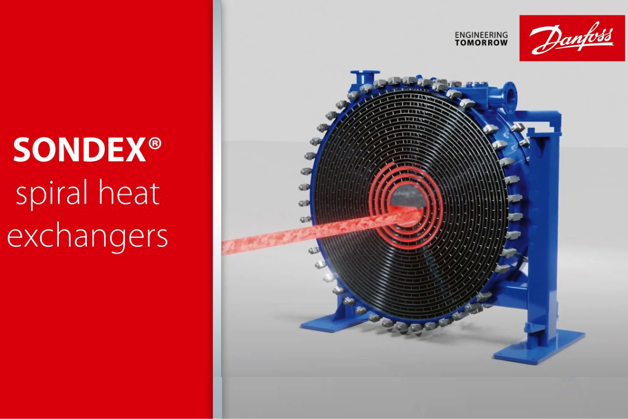

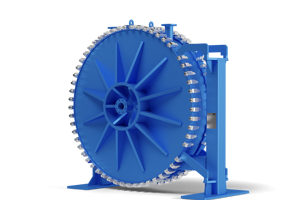

Exceptionally well-suited for sludges, slurries, waste water, fouling, liquids with high viscosity, and liquids that contain fibers and solids, our SONDEX® spiral heat exchangers are the definitive solution for applications that require treatment of challenging fluids. The design allows for a countercurrent flow that makes it possible to achieve very close temperature approaches.

Since we use coiled metal sheets instead of tube bundles, we can achieve very high thermal performance without sacrificing the channel gap that lets the media flow unimpeded.

The spiral coil itself also contributes to the turbulent flow, and the single-channel design helps alleviate fouling with a “self-cleaning” effect. Accumulated deposits create local increases in velocity, creating a scrubbing effect that is enough to loosen the build-up in fouling in most cases. This allows our SONDEX® spiral heat exchangers to operate in very long sessions without maintenance or cleaning.

Some media, however, are so challenging that the heat exchanger requires more frequent maintenance and cleaning. With this in mind, we have designed hinged covers that are sealed with C-clamps, creating a swing door that is very easy to open and close without any special tools required, letting you access the entire coil for inspection and cleaning.

Features and benefits

-

Single-channel design that generates high shear rates which contribute to a self-cleaning effect, preventing clogging of the unit. Spiral heat exchangers are the perfect solution for challenging, high-viscosity media.

-

The channel size is selected to fit the flow and qualities of the media. The many variations in diameters and widths of the spiral coil allow for many different combinations, which mean that we can create the optimal solution for every duty.

-

Designed to handle a very aggressive temperature program and with a wide range of materials and plate thicknesses available, we customize each spiral heat exchanger to match the requirements of any application.

-

Limited need for maintenance and cleaning ensures extended operational uptime. If the need for cleaning arises due to particularly difficult media, the hinged covers provide easy access to the entire heat transfer surface.

-

Very compact solutions, our spiral heat exchangers have minimal space requirements. Despite their small stature, the long, curved flow paths allow for very high heat transfer coefficients up to twice as high as their shell and tube counterparts.

Applications

- Dairy/food/beverage industry

- Biogas industry

- Wastewater industry

- Pulp and paper industry

- Heavy industry

- Petrochemical industry

- Chemical industry

Technical specifications

- Connections from DN32 to DN300 (1 1/4" to 12")

- (Frames designed according to FEA and PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards)

- Shell materials: Carbon steel, stainless steel

- Spiral materials: Carbon steel, stainless steel

- Working pressure up to 16 bar (145 psi)*

- Working temperatures from -20 °C to 200 °C (-4 °F to 392 °F)

*Higher pressure available upon request

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | A world of heat exchangers | Romanian, Moldavian, Moldovan | Romania | 10 Oct, 2024 | 9.7 MB | |

| Brochure | A world of heat exchangers | Bulgarian | Bulgaria | 04 Oct, 2024 | 5.3 MB | |

| Brochure | A world of heat exchangers | English | Multiple | 15 Sep, 2025 | 4.7 MB | |

| Brochure | SONDEX® Free Flow sugar brochure | English | Multiple | 27 Nov, 2024 | 7.2 MB | |

| Data sheet | SONDEX® Spiral heat exchanger - SonSPV | English | Multiple | 25 Oct, 2022 | 769.7 KB | |

| Brochure | Spiral heat exchanger | English | Multiple | 12 Feb, 2024 | 4.5 MB | |

| Brochure | Брошура_Вдосконалені рішення теплообміну | Ukrainian | Ukraine | 01 Oct, 2025 | 3.8 MB |

Related products

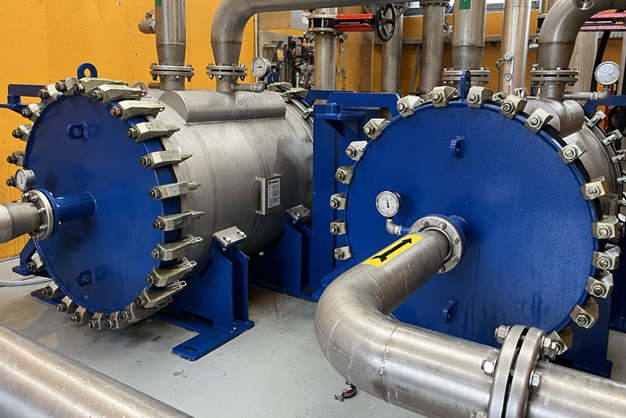

Our Plate and shell heat exchangers are perfect choices for condensation and steam heating duties. A fully welded plate pack makes the heat exchangers well-suited for handling aggressive media as well as high pressure levels and temperatures. Less space demanding and much lighter in weight, they are good replacements for shell and tube heat exchangers.

Exceptionally well-suited for sludges, slurries, waste water, fouling, liquids with high viscosity, and liquids that contain fibers and solids, our SONDEX® Spiral heat exchangers are the definitive solution for applications that require treatment of challenging fluids. The design allows for a countercurrent flow that makes it possible to achieve very close temperature approaches.

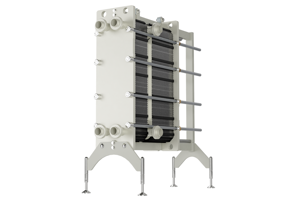

SONDEX® standard plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. We have the largest plate portfolio in the world, and customize each heat exchanger to meet your exact requirements. Innovative technologies and smart design make our traditional plate heat exchangers a stellar investment.

SONDEX® Free Flow plate heat exchangers are the preferred choice for applications that use media with particle-rich contents, fouling tendency, or high viscosity. Each Free Flow heat exchanger is customized to suit your application and media type, with contact-free plate channels for an unimpeded flow and long intervals between cleaning.