The Series 45 family of pumps are a high-performing and flexible option for new machine applications needing variable displacement open-circuit flow in the medium pressure range (up to 310 bar). With a full line of displacements, controls, and mounting options, the Series 45 modular design approach reduces your time to market and provides a more competitive, reliable product to your customers.

Optimized system design

When you equip your machine with Series 45 pumps, choosing valves and controls that are made to work together can truly optimize your machine. Series 45 pumps are PLUS+1® compliant and our electronic controls are ready to go with plug and play software using the Danfoss PLUS+1® GUIDE programming environnent. They are also the perfect match for PVG proportional valves, providing efficient and precise machine movement across a wide range of flow requirements.

A broad portfolio for maximum control

Series 45 pumps can be equipped with a broad range of control options. In addition to a full range of standard pressure compensation and load sensing controls, we offer many controls for today’s electrified systems needing electronic actuation or power management.

Our optimized Fan Drive Control (FDC) comes in a slim single spool package and is specifically engineered for ideal cost-effective regulation of fan speed in cooling, cleaning, and vacuum fan systems.

Electronic Displacement Control (EDC) – available exclusively on the K2-frame – is an excellent choice for simple and robust control of pump flow to machine functions. This control can reduce dependency on intermediate valves for motor applications, provide dynamic maximum displacement limitation for auxiliary flow functions, or provide power management for overload protection.

Electronic Torque Limiting (ETL) controls are a premium choice in the industry for managing of power or torque. Use these controls when you want to maximize productivity, minimize fuel consumption, or protect your system from overloading conditions. Not only can this system solution protect diesel engines from stalling, but it can also be used to limit current draw through electric motor inverters.

Unique features for unique customers

We understand that every customer is different and therefore your requirements are too. Series 45 helps meet the important and diverse needs of the mobile equipment market with features like a lead-free valve plates.

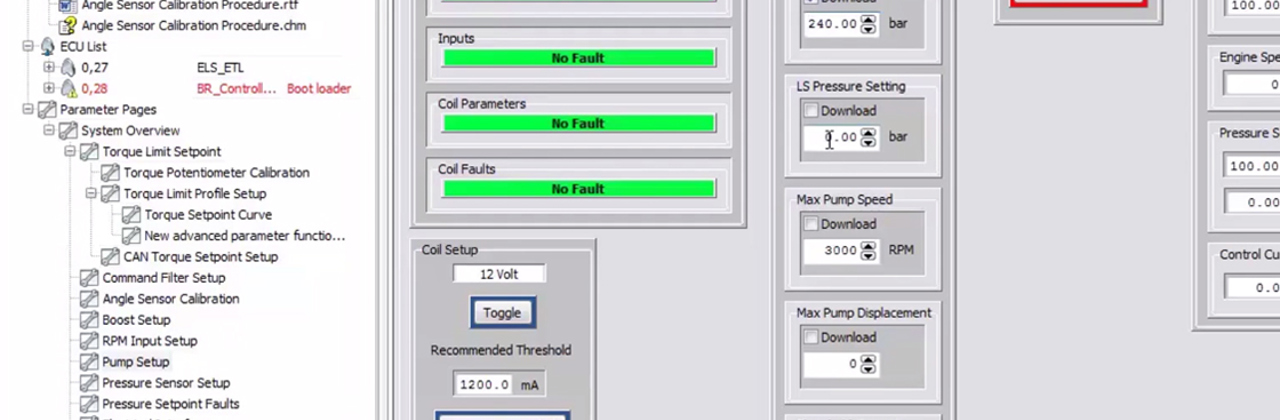

ETL service tool how to demonstration

eHydraulic Power Module

This sub-system solution combines our synchronous reluctance assisted permanent magnet (SRPM) motor together with axial piston variable displacement technology, delivering the highest proven efficiency in heavy duty vehicles.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Data sheet | Series 45 Axial Piston Open Circuit Pump ETL Control Data Sheet | English | Multiple | 30 Jan, 2019 | 1.7 MB | |

| User guide | Series 45 Axial Piston Open Circuit Pump Technical Information | Japanese | Japan | 10 Jun, 2025 | 17.6 MB | |

| User guide | Series 45 Axial Piston Open Circuit Pump Technical Information | German | Germany | 08 Mar, 2015 | 1.8 MB | |

| User guide | Series 45 Axial Piston Open Circuit Pump Technical Information | Japanese | Multiple | 10 Jun, 2025 | 15.4 MB | |

| User guide | Series 45 Axial Piston Open Circuit Pump Technical Information | English | Multiple | 04 May, 2025 | 14.0 MB | |

| User guide | Series 45 Axial Piston Open Circuit Pump Technical Information. | Chinese | Multiple | 21 Sep, 2023 | 14.3 MB | |

| Data sheet | Series 45 Axial Piston Open Circuit Pumps Data Sheet | English | Multiple | 04 Dec, 2025 | 1.8 MB | |

| Operating guide | Series 45 Axial Piston Pumps Electronic Torque Limiting Control User Manual | English | Multiple | 06 Mar, 2024 | 8.8 MB | |

| User guide | Series 45 Frame G Axial Piston Open Circuit Pump Technical Information Manual | English | Multiple | 09 Mar, 2015 | 1.3 MB | |

| User guide | Series 45 Frame H Axial Piston Open Circuit Pump Technical Information Manual | English | Multiple | 09 Mar, 2015 | 1.6 MB |

Related products

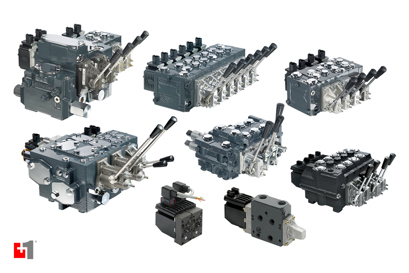

Our compensated proportional valves also known widely as Danfoss PVG (Proportional Valve Group), are designed with modularity and precision at their core. Our PVG design toolbox allows us to create valve stacks tailored to any work and control requirements. From simple load-sensing to advanced electrically controlled load-independent proportional valves, our solutions reduce wear and tear on system components, extending vehicle lifespan. Seamless integration is guaranteed, regardless of valve combination.

Fast, accurate and intelligent operation with our plug and perform PVE actuators – under any operating and environmental conditions.

Integrated Circuit Solutions (ICS) cartridges and manifolds offer an unlimited number of high-quality solutions that can be customized to meet your specific machine’s requirements.

Danfoss is taking functional safety to the next level with a full program of state-of-the-art rotary position sensors, wire position sensors, and inclination sensors. All three sensor types come as both single and redundant sensor types, making the complete portfolio suitable for safety-critical applications.

Related applications

Farmers need agricultural machines that deliver the same high productivity every season. Hydraulic solutions from Danfoss ensure world-class performance from each machine, and a comfortable, stress-free working environment for their operators.

Space is limited on construction sites, and there are people working everywhere. Contractors need machines that can safely maneuver in a tight spot. At the same time they still need to be powerful enough to get the job done. At Danfoss, we deliver the components, software, and controls that enable your machines to run safely, efficiently and effectively.

Cranes and other large handling machines are required to operate within very specific load ranges. Danfoss provides pressure transmitters that supply load limiting systems with crucial data, safeguarding your equipment, your load, and your operator.

Rough, sloping terrain and cramped working conditions call for robust and reliable forestry machines. We make sure you can manage everything from cutting trees and transport to preparing the forest floor for replanting. We have the smart hydraulic solutions your machines need for precise and efficient forestry operations.

Think about the heaviest challenges in the open mining, road building and construction industry. Tasks such as cutting through rock or the Arctic permafrost; compacting thick layers of hot asphalt. As well as lifting huge, prefabricated wall panels into place.

Upstream Offshore Oil and Gas activities are making up nearly 30% of global crude oil production. These are some of the harshest operating environments on the planet. Drilling in waters up to 3,000 meters deep requires equipment that is reliable and safe. this can help to maximize operating productivity and prevent unexpected downtime.

Related solutions

As the global market leader in steering components and systems, Danfoss equips everything from small lawn machines to the largest dump trucks.

Case stories

Danfoss Power Solutions is supplying its Editron eDrive to VTS Track Solutions to propel the company’s new Fero Tracked Carriers. The ETP-10 and ETP-20 are remote-controlled battery-electric carriers designed for effortless material transport in construction, forestry, landscaping, workshops, and other applications. The low-voltage eDrive was the perfect match, offering high efficiency and reliability as well as precise control.

World’s first fully electric large foundation rig with Danfoss Editron components.

Learn how the Danfoss Series 45 ETL pump eliminated stalling, reduced costs, and delivered efficiency improvements for a truck-mounted crane produced by Türkiye-based OEM MPG.

Junttan, a Finnish hydraulic piling equipment manufacturer, built the world’s first fully-electric pile driving rig in order to offer a sustainable option to their customers.

A new generation of electric skid steer loaders is bringing smarter functionality to this important market segment, enhancing operator ease of use and productivity. Helping to facilitate this transition are intelligent electronic controls and software from Danfoss Power Solutions.

Danfoss Editron and Spierings Mobile Cranes work together to develop mobile cranes and lifts that generate zero emissions. As of 2020, all the machines manufactured by Spierings have electric functionality. This use case explores the partnership.