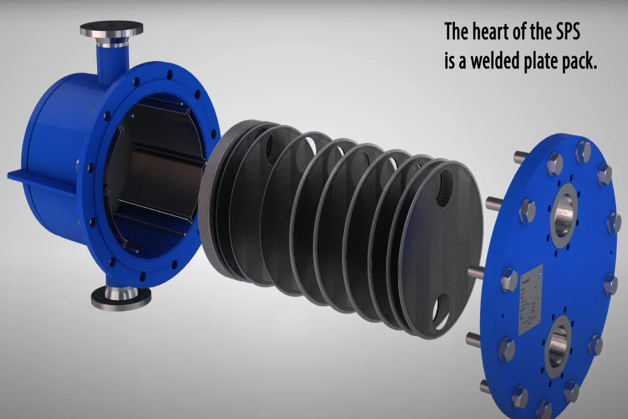

Our Danfoss plate and shell heat exchangers are perfect choices for condensation and steam heating duties. A fully welded plate pack makes the heat exchangers well-suited for handling aggressive media as well as high pressure levels and temperatures. Less space demanding and much lighter in weight, they are good replacements for shell and tube heat exchangers.

Danfoss plate and shell heat exchangers combine the strengths of both shell and tube heat exchangers and plate heat exchangers, retaining the high working pressure and temperatures of the former coupled with the high efficiency of the latter. A “best of both worlds” solution, our plate and shell heat exchangers provide unmatched performance for a wide range of applications, particularly vapor condensation duties.

Features and benefits

-

Very adaptable heat exchanger. An excellent choice for handling condensation duties. They are also perfect steam heaters of clean fluids, demineralized water, and clean thermal oils.

-

The heat exchanger is designed to be highly resistant to thermal shocks as well as thermal and pressure fatigue making it very well-suited for cyclic duties and other duties with sudden, large fluctuations in temperature.

-

Available in both bolted and fully welded designs. The fully welded types can handle higher temperatures and pressure levels than the bolted types, but cannot be opened for cleaning. This can instead be done with CIP (Cleaning in Place) systems.

Applications

- HVAC industry

- Marine/offshore industry

- Dairy/food/beverage industry

- Sugar industry

- Biogas industry

- Pulp and paper industry

- Heavy industry

- Mining industry

- Petrochemical industry

- Chemical industry

- Condensation

- Steam heating

- Oil coolers

- Gas heaters/coolers

Technical specifications

- Connections from DN25 to DN300 (1" to 12")

- Frames designed according to FEA and PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards

- Plates made from AISI 304/316, titanium*

- Shell materials: Carbon steel, stainless steel

- Working pressure up to 40 bar (580 psi)

- Working temperature -10 °C up to 250 °C (14 °F to 482 °F) for bolted types and up to 400 °C (752 °F) for the fully welded types

*other materials available upon request

In this video we will show you the construction, assembly, and working principle of a plate and shell heat exchanger.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | A world of heat exchangers | Romanian, Moldavian, Moldovan | Romania | 10 Oct, 2024 | 9.7 MB | |

| Brochure | A world of heat exchangers | Bulgarian | Bulgaria | 04 Oct, 2024 | 5.3 MB | |

| Brochure | A world of heat exchangers | English | Multiple | 15 Sept, 2025 | 4.7 MB | |

| Brochure | Heat exchangers for the power industry | English | Multiple | 19 Nov, 2024 | 4.8 MB | |

| Data sheet | SONDEX® Plate and shell heat exchanger (SPS) | English | Multiple | 25 Oct, 2022 | 1.4 MB | |

| Brochure | SPS plate and shell heat exchangers | English | Multiple | 12 Feb, 2024 | 4.5 MB | |

| Brochure | Брошура_Вдосконалені рішення теплообміну | Ukrainian | Ukraine | 01 Oct, 2025 | 3.8 MB |

Related products

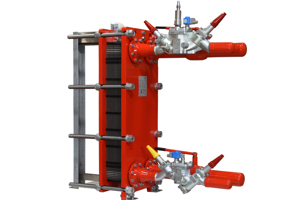

The semi-welded plate heat exchangers are optimized for industrial applications. The semi-welded plate heat exchangers from Danfoss is designed for ammonia systems and can be used for applications such as Condensers, flooded and pumped evaporators, Sub-coolers, Desuperheaters, Superheaters, Economizers and Oil coolers.

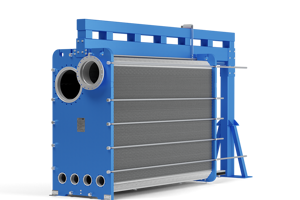

Save time and money with MCHE standard products. The introduction of micro channel heat exchanger condensers, which combine resource and energy efficiency with minimal use of refrigerants, is enabling the development of leaner, greener solutions. Select one of our standard products and you can buy any quantity of condensers, any time, large or small, directly from stock.

SONDEX® evaporators are designed to handle advanced evaporation duties. Using semi-welded plate cassettes, the media are guaranteed to never mix. The plate cassettes are designed to ensure the optimal level of turbulence on both sides, while providing an even distribution of the media for superior performance and product quality.

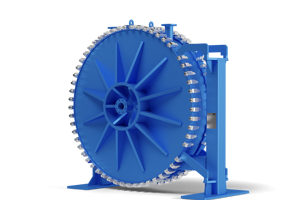

Exceptionally well-suited for sludges, slurries, waste water, fouling, liquids with high viscosity, and liquids that contain fibers and solids, our SONDEX® Spiral heat exchangers are the definitive solution for applications that require treatment of challenging fluids. The design allows for a countercurrent flow that makes it possible to achieve very close temperature approaches.

Our SONDEX® Plate and shell heat exchangers (SPS) are perfect choices for condensation and steam heating duties. A fully welded plate pack makes the heat exchangers well-suited for handling aggressive media as well as high pressure levels and temperatures. Less space demanding and much lighter in weight, they are good replacements for shell and tube heat exchangers.